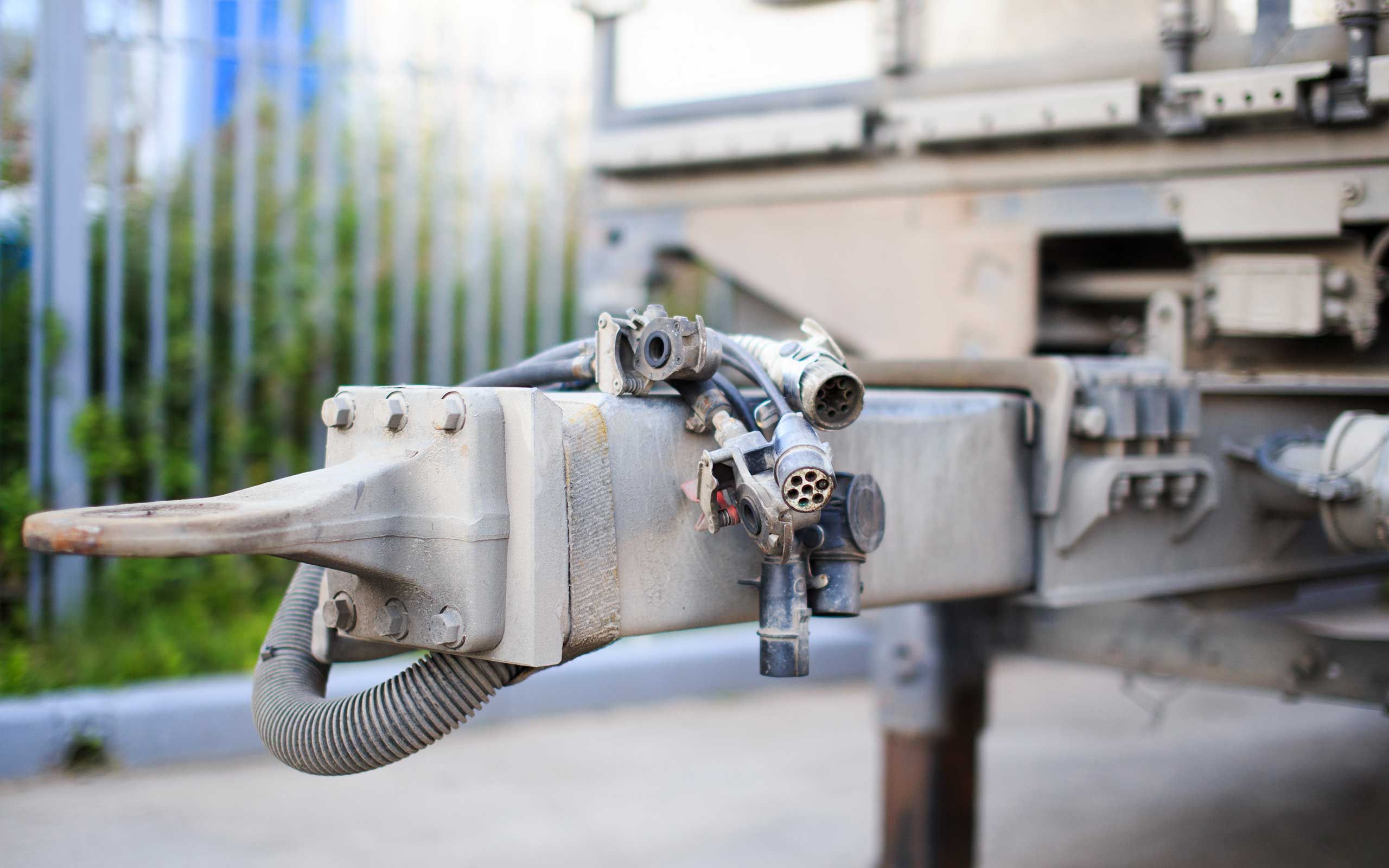

Coupler Replacement

No one does more kingpin or upper coupler replacements than Atlantic Trailer.

Roughly 30% of all kingpins used on trucks in the United States and Canada do not meet current standards for acceptable tolerances. Every Kingpin eventually needs replacement. If you regularly maintain your equipment, a new kingpin or upper coupler could double the life of your trailer. Whether it’s for a single trailer or an entire fleet, your company will benefit from a new level of service by choosing Atlantic to meet your repair needs.

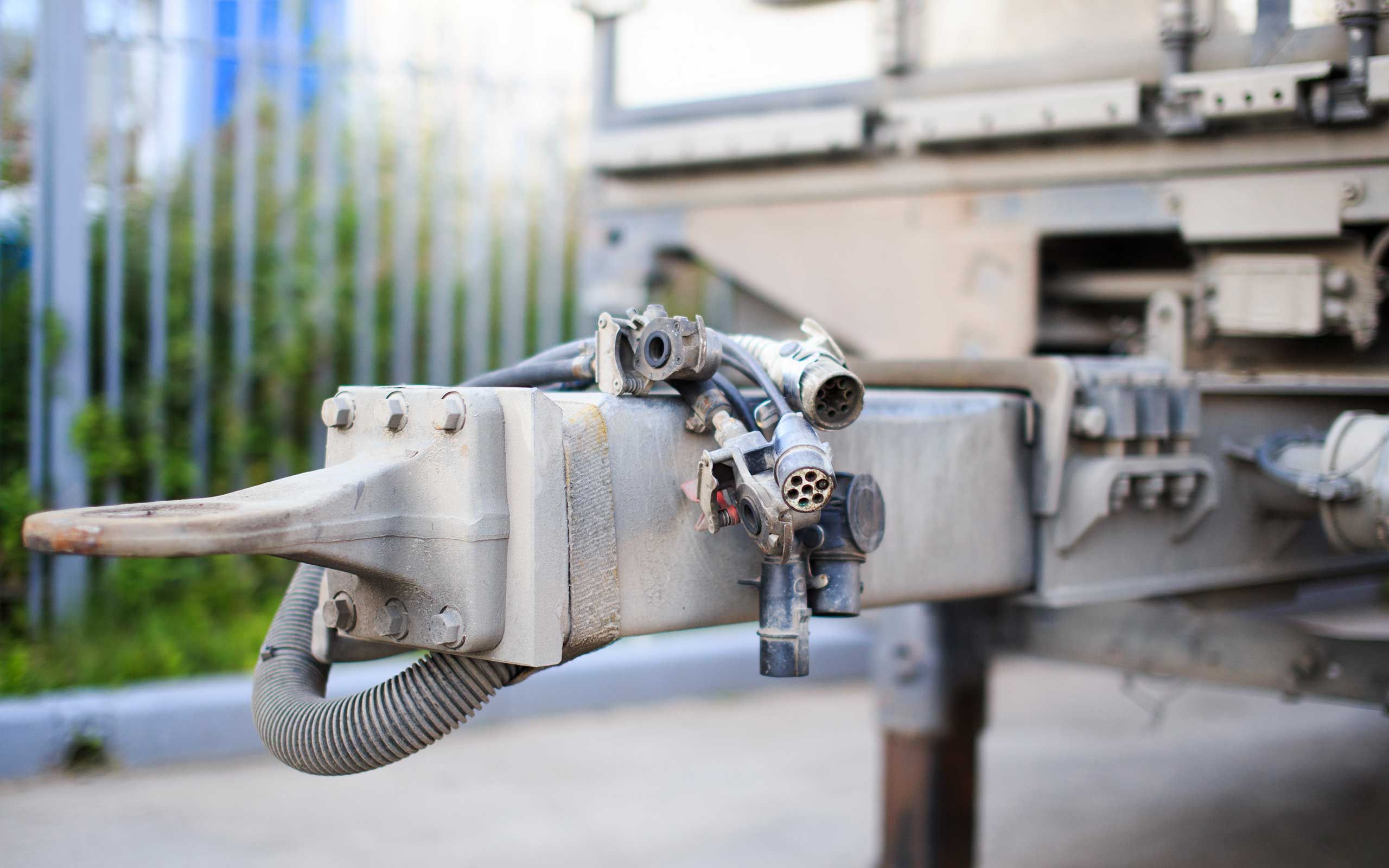

Kingpin maintenance and replacement recommendations

Inspecting and maintaining the trailer upper coupler and kingpin is as important as inspecting and maintaining the fifth wheel. To ensure safe kingpin/fifth wheel coupling, we recommend taking the following service measures every three months or 30,000 miles.

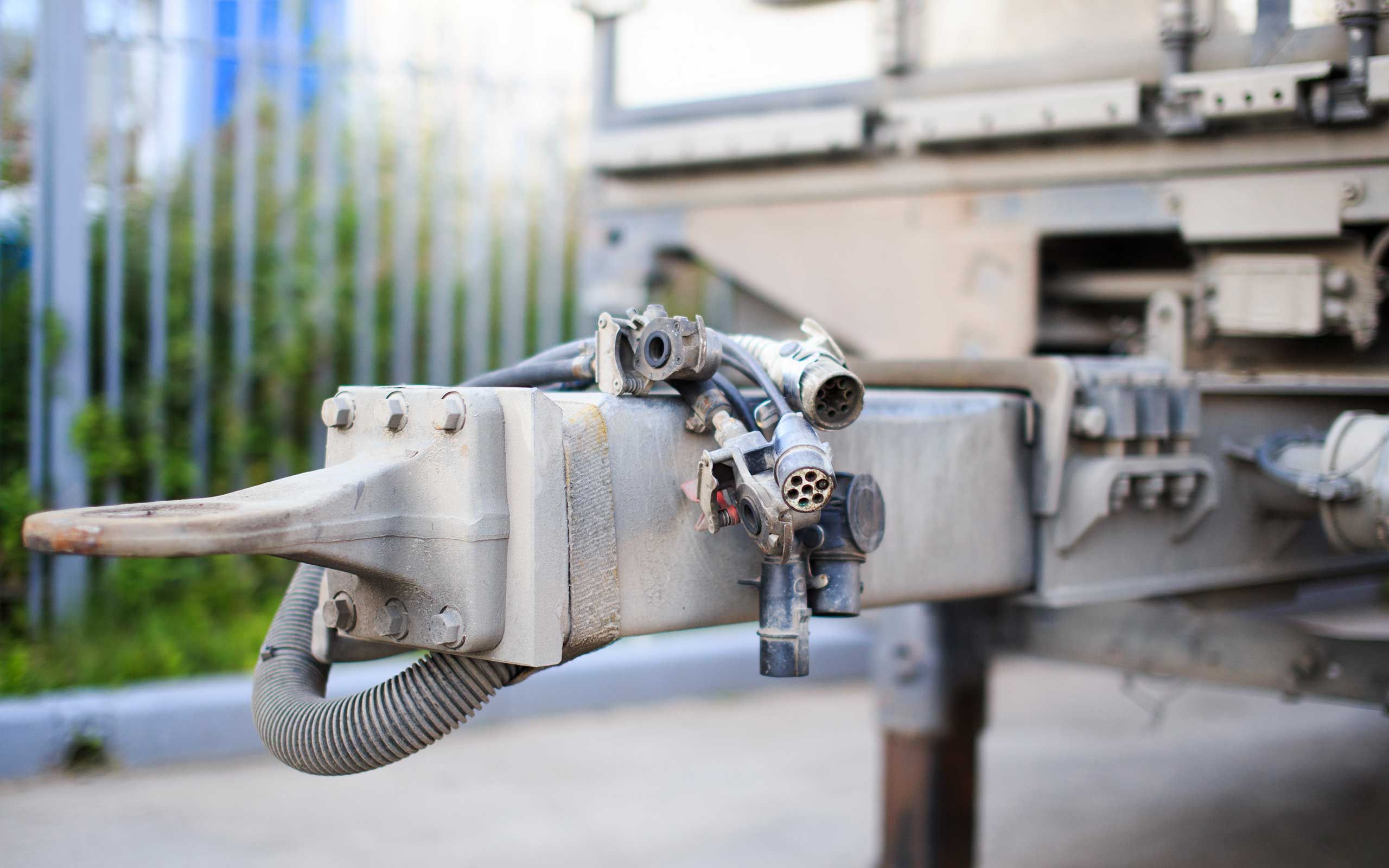

Upper coupler plate flatness

Use a 48” straight edge to check flatness in all directions. Bumps, valleys or warping of the plate will cause uneven loading of the fifth wheel, damaging the top plate and causing poor lock life. If flatness exceeds specifications, replace the trailer upper coupler plate.

Inspect the kingpin for wear

Using a Kingpin gauge, check the wear on both the 2˝ and 2.88˝ diameters. If wear of 1/8˝ (.13˝) is found, replace the kingpin.

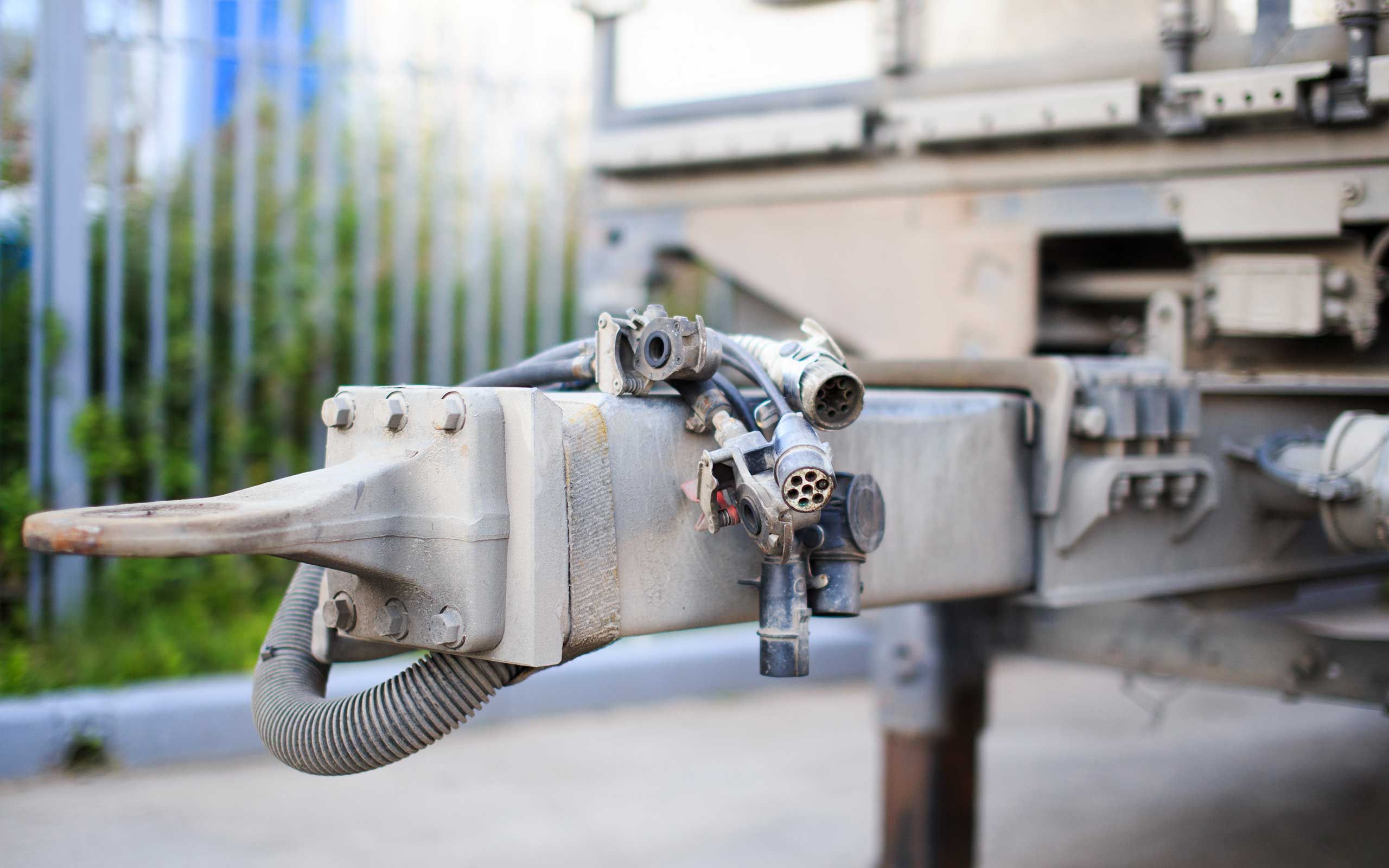

Check the kingpin mounting

In addition to being a safety hazard, a loose mounting will cause excessive chucking and rapid lock wear. Reinstall or replace any kingpin that is not securely mounted.

Check the kingpin for damage

Inspect the kingpin for nicks, gouges, deformities or cracks that may interfere with or affect the safe use of the kingpin. Replace the kingpin if damage is discovered.